- Plc Ladder Diagram Software

- Ladder Diagram Software Online

- Best Ladder Diagram Software

- See Full List On Plcacademy.com

- Ladder Logic - Wikipedia

1. What Is a Ladder Diagram?

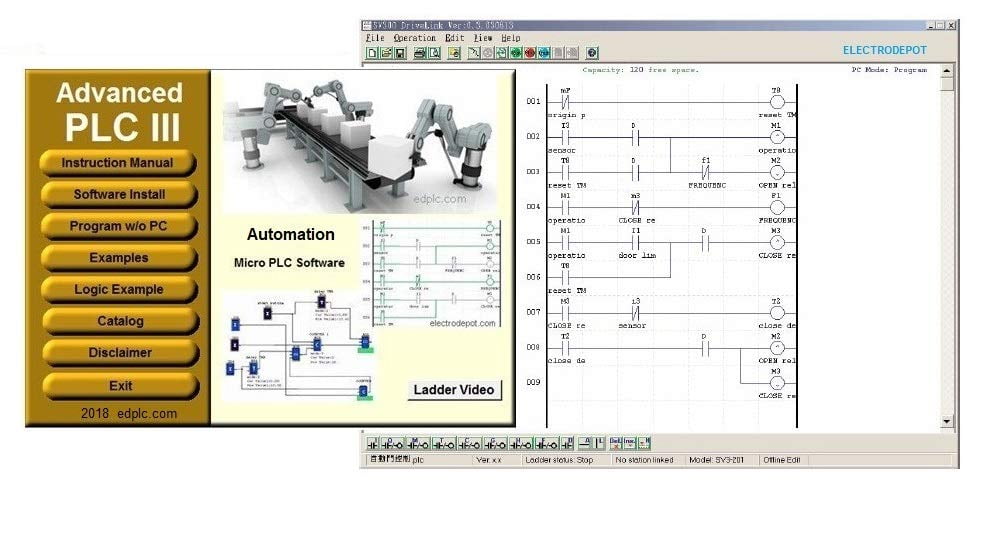

Jun 27, 2015 Ladder Diagram for Motor Control. Motor control can be done with a PLC program. In fact, the PLC is a common choice for controlling AC motors. Here are some examples of ladder diagrams for motor control. Star Delta PLC Ladder Diagram. One of the most common ways to start an AC motor is by first starting the motor in star connection. Ladder Diagram Example A manual mixing operation is to be automated using sequential process control methods. The process composed of three steps: a.) filling a tank to a predetermined level b.) agitating the liquid for 30 minutes c.) draining the tank for use in another part of process Does the ladder logic schematic that follows perform. Ladder Logic Simulator A ladder logic simulator is a software application that lets you simulate the operation of a PLC ladder diagram with a personal computer, mobile phone or tablet. It allows you to test your PLC ladder diagram without the need to purchase any PLC hardware. In TRiLOGI all the I/Os must be defined with unique label names prior to using them to construct the ladder program. Up to 8 characters of alpha-numeric names can be defined which means you can create ladder diagram using far more meaningful names such as 'Start' and 'Fire' instead of 001, 205 etc.

Ladder diagrams are advanced schematics widely used to record logic structures for industrial controls. These are called ladder diagrams because they mimic a ladder, with two vertical rails (supply power) and as many 'rungs' (horizontal lines) as there are to represent control circuits.

The load device (lamp, relay coil, solenoid coil, etc.) is drawn almost always on the right-hand side of the rung in ladder diagrams. Although it doesn't matter electrically where the relay coil is within the rung, it does matter that the end of the power supply of the ladder is grounded, for stable operation.

2. Application Scenarios of Ladder Diagrams

- Every system in the relay rack will be depicted with a symbol on the diagram of the ladder indicating the relations between such devices. Furthermore, other things beyond the relay rack, such as pumps, heaters, and so on, will also feature on the schematic of the ladder.

- Ladder logic has developed into a programming language, describing a system through a graphical diagram based on the relay logic hardware circuit diagrams.

- Ladder logic is used to build a programmable logic controller (PLC) software and is used in industrial control applications.

- For basic yet essential control systems or for reworking old hardwired relay circuits, Ladder logic is useful.

- This has also been used in very advanced automation systems as programmable logic controllers have become more sophisticated.

- Ladder logic should be described as a language focused on rules, rather than a language of procedures. A ladder 'rung' represents a rule.

3. Benefits of Using a Ladder Diagram

- Intuitive and self-documenting. A ladder diagram provides superb schematic interpretation focused on well-understood principles of circuit architecture.

- The learning curve to get going with a ladder diagram is very small because of the accessibility of the environment; simple programming skills grow rapidly.

- This has made the ladder diagram especially common for applications that involve staff without technical experience to repair or manage, like certain electricians or plant technicians.

- The ladder diagram is intended to replicate electrical circuits, it is a perfect way of reflecting abstract logic of course. A ladder diagram is pretty intuitive for digital logic.

4. Why Is a Ladder Diagram Used for PLC Programming?

Ladder logic is a programming language used for PLC (Programmable Logic Controller) programming. It is a graphical PLC programming language which uses ladder diagrams to express logic operations with symbolic notation, much like the rails and rungs of a typical relay logic circuit.

In order to bring industrial automation applications, it is used by engineers and electricians to execute mathematical, linear, measuring, pacing, and arithmetic functions. It is a common process from which to program a PLC. Ladder logic programming is still used now since the basic concepts of system and process control are still the same.

5. How To Read a Ladder Diagram?

Microprocessors like those used in PLC's and personal computers function at a binary code level. You've read of the word 'neutral' presumably. This applies to the idea that in one of two States, things should be conceived about. Can describe the states as:

- 1 or 0

- Real or Negative

- Tall or Low

- On or Off

- Yes or No

The ladder logic uses symbolic expressions and a graphical editor to write and read ladder diagrams which make it easier for us humans to understand. If we convert a real-life occurrence into ladder language we will symbolically articulate it in the form of a typically open communication (NO). This occurrence may be anything like clicking a button or triggering a limit shift.

6. How to Create a Ladder Diagram Online

The rails in a ladder diagram depict the supply wires of a regulating relay logic circuit. On the left line, there is a positive voltage supply track, and on the right side, a negative voltage track.

In a ladder diagram, the logic flow is from the left-hand rail to the right-hand rail. There are seven fundamental aspects of a ladder diagram which are important to learn when applying a ladder logic system in a PLC. They are names and statements concerning lines, rungs, inputs, outputs, logic expressions, address notation/tag names. Some of these are essential, and some are optional.

- Rails In a ladder diagram there are two rails which are drawn as vertical lines going down the foremost ends.

- Rungs The rungs are drawn horizontally and link the rails to the statements of logic.

- Inputs The inputs are actual control acts such as pushing a push-button or activating a cap switch.

- Outputs Outputs are electronic machines which are turned on and off like an electric motor or a solenoid lever.

- Logic Expressions The logic expressions are used to formulate the desired control operations in combination with the inputs and outputs.

7. Ladder Diagram Example

The above diagram depicts a ladder logic programming example, illustrating an input/output circuit.

8. Key Takeaways

The Ladder diagrams (sometimes called 'ladder logic') are a type of electrical notation. This symbology is sometimes used to demonstrate the interconnection of electromechanical switches and relays. A digital depiction of the features of the programme.

EdrawMax is a conceptual diagramming program that helps construct the flowcharts, hierarchical charts, mind maps, network diagrams, floor plans, and ladder diagrams. All shapes and clipart are vector format design, which means your ladder diagram will never get blurred, irrespective of what size you change it to.

Ladder logic is a programming language that is used to program a PLC (Programmable Logic Controller). It is a graphical PLC programming language which expresses logic operations with symbolic notation using ladder diagrams, much like the rails and rungs of a traditional relay logic circuit.

Ladder logic is a fast and simple way of creating logic expressions for a PLC in order to automate repetitive machine tasks and sequences. It is used in a multitude of industrial automation applications. Some industrial automation application examples where PLC ladder logic is used include….

- Material Handling Conveyor System.

- Pallet Packing and Strapping.

- Ball Mill Lubrication System.

- Logistics Package Conveying and Sorting.

- Cement Batching.

- Beverage Bottling and Labeling.

- Hopper and Tank Level Control.

- Air and Liquid Flow and Pressure Control.

In the good ol’ days, machine and process automation was accomplished using a hard wired control system known as relay logic. With the advent of microprocessors and the invention of the PLC, relay logic quickly became superseded by programming languages such as ladder logic.

Why is Ladder Logic Popular?

Ladder logic is the most popular method of PLC programming because it is a graphics based programming language that resembles electrical schematic drawing. Engineers, electricians and students that are already familiar with electrical schematic drawings find making the transition from an electric circuit to ladder logic relatively easy, compared to other text based programming languages.

When programming ladder logic in a PLC, the graphic, drag and drop nature of ladder diagrams helps you formulate code quickly and easily. Ladder logic also helps you easily trouble shoot your code because you can visually see the flow of logic from the LHS start rail, through the logic symbols and to the RHS end rail.

Learning the Basics of Ladder Logic

It’s relatively easy to learn the basic concepts of ladder logic programming, even if you don’t have experience with electric circuits. Take comfort in knowing that ladder logic is the quickest and easiest PLC programming language to learn.

In order to help you learn the basics of ladder logic we will cover the following….

- Introduce the ladder diagram.

- Examine the seven basic parts of a ladder diagram.

- Identify the binary and logic concepts used in ladder logic.

- Reveal the hidden ladder logic functions that are automatically built into the structure of the ladder diagram.

- Discover the five fundamental logic functions that are essential to know.

So let’s begin….

What is a Ladder Diagram in a PLC?

A ladder diagram is the symbolic representation of the control logic used for ladder logic programming of a PLC. Ladder diagrams have horizontal lines of control logic called rungs and vertical lines at the start and end of each rung called rails. The structure of a ladder diagram actually looks like a ladder, hence the name “ladder diagram”.

There are two differences between an electrical schematic and aladder diagram. The first difference is the control logic in an electricalschematic is represented using components whereas in a ladder diagram symbolsare used. The second difference is the control logic execution in an electricalschematic is as per the operation of an electrical circuit whereas in a ladderdiagram it relies on the methodical nature of the PLC scan.

Why is a ladder diagram used for PLC programming?

The reason why ladder diagrams are used for PLC programming is because theearly control system designers were accustomed to relay logic control circuits andladder diagrams closely mimic these. They preferred to use ladder diagramsinstead using text based programming languages ofthe day like C, BASIC, Pascal and FORTRON. The other reason ladderdiagrams are used is because factory maintenance staff already understand howto read relay control circuits so using ladder diagrams for programming a PLC meantthey were easily able to troubleshooting control system problems.

Ladder diagrams help you to formulate the logic expressions in graphical form that are required to program a PLC. They represent conditional, input and output expressions as symbols. So writing a PLC program using ladder diagrams is similar to drawing a relay control circuit.

Ladder Diagram (LD) is the official name given in the international PLC programming standard IEC-61131. But, these days the terms ladder diagram, ladder logic diagram, ladder drawing, ladder control, ladder circuit, control logic diagram and logic diagram (to name a few) are all used to describe relay logic circuits and ladder logic programming.

So don’t get too caught up in the specific definition of each of these expressions, they kind of generally all mean the same thing. At the end of the day most people will know what you are talking about anyway. Personally, I use the term ladder logic for PLC programming and relay logic for relay control circuits.

To access the body responsible for maintaining the IEC-61131 standard please click here.

How to Draw Ladder Logic Diagrams

Ladder logic diagrams are drawn in a similar way to relay logic circuit. However, ladder logic diagrams express logic operations using symbolic notation rather than circuit components.

The rails in a relay logic circuit represent the supply wires of a relay logic control circuit. However, in ladder diagrams, the rails represent the start and end of each line of symbolic code.

The rungs in a relay logic circuit represent the wires that connect the components together. However, in a ladder diagrams, the rungs represent the logic flow through the symbolic code.

When implementing a ladder logic program in a PLC there are seven basic parts of a ladder diagram that critical to know. They are rails, rungs, inputs, outputs, logic expressions, address notation/tag names and comments. Some of these elements are essential and others are optional.

To help understand how to draw ladder logic diagrams the seven basic parts of a ladder diagram are detailed below….

- Rails – There are two rails in a ladder diagram which are drawn as vertical lines running down the far most ends of the page. If they were in a relay logic circuit they would represent the active and zero volt connections of the power supply where the power flow goes from the left hand side to the right hand side.

- Rungs – The rungs are drawn as horizontal lines and connect the rails to the logic expressions. If they were in a relay logic circuit they would represent the wires that connect the power supply to the switching and relay components. Each rung is numbered in ascending sequential order.

- Inputs – The inputs are external control actions such as a push button being pressed or a limit switch being triggered. The inputs are actually hardwired to the PLC terminals and represented in the ladder diagram by a normally open (NO) or normally closed (NC) contact symbol.

- Outputs – The outputs are external devices that being are turned on and off such as an electric motor or a solenoid valve. The outputs are also hardwired to the PLC terminals and are represented in the ladder diagram by a relay coil symbol.

- Logic Expressions – The logic expressions are used in combination with the inputs and outputs to formulate the desired control operations.

- Address Notation & Tag Names – The address notation describes the input, output and logic expression memory addressing structure of the PLC. The tag names are the descriptions allocated to the addresses.

- Comments – Last but by not least, the comments are an extremely important part of a ladder diagram. Comments are displayed at the start of each rung and are used to describe the logical expressions and control operations that the rung, or groups of rungs, are executing. Understanding ladder diagrams is made a lot easier by using comments.

How to Read Ladder Logic

Ladder logic is basically read from the left hand rail to the right hand rail and from the first rung to the last rung (left to right and top to bottom). The rungs contains input symbols that either pass or block the logic flow. The last element of each rung is an output symbol which is the result of the logic expressions contained in that rung.

To start reading ladder logic we need to know some basic binary concepts and how they apply to ladder logic, how ladder logic is executed and the basic logic functions that are built into each rung. Let’s begin….

The Binary Concept Applied to Ladder Logic

Plc Ladder Diagram Software

Microprocessors, like the ones found in PLCs and personal computers operate on the binary concept. You’ve probably heard of the term ‘binary’. It refers to the principle that things can be thought of in one of two states. The states can be defined as:

True or False

1 or 0

On or Off

High or Low

Yes or No

Microprocessors love binary…. 10101011101000111010001010100010100100101010010011.

I don’t know about you, but my head hurts just looking at that. Luckily ladder logic uses symbolic expressions and a graphical editor for writing and reading ladder diagrams making it easier for us mere humans to comprehend.

In a PLC, binary events are expressed symbolically using ladder logic in the form of a normally open contact (NO) and normally closed contact (NC). The normally open contact (NO) is TRUE when the event is active and FALSE when the event is NOT active. While the normally closed contact (NC) is FALSE when the event is active and TRUE when the event is NOT active.

Let me explain NO and NC contacts a little further ….

Normally Open Contact (NO) in Ladder Logic

The event associated with a normally open contact (NO) can be TRUE or FALSE. When the event is TRUE then it is highlighted green and the logic flow can move past it to the next logic expression. Just like the current flow in an electric circuit when a switch is turned on.

Let’s call a certain PLC input event ‘A’. This PLC input event could be something like a button being pushed, a limit switch being activated or a temperature switch being triggered.

PLC input event ‘A’ follows the binary concept and has one of two states, TRUE or FALSE. The ladder logic truth table for a normally open contact (NO) which denotes PLC input event ‘A’ is shown below….

Normally Closed Contact (NC) in Ladder Logic

The event associated with a normally closed contact (NC) can be TRUE or FALSE. The result of the normally closed contact (NC) is basically the opposite state of an event that occurs. So, if PLC input A is FALSE the result will be TRUE. And vise versa when PLC input A is TRUE the result will be FALSE.

The normally closed contact (NC) is considered to be a ladder logic NOT function. It is sometimes referred to as reverse logic. Check out the truth table below….

If we translate a NOT function into a ladder logic diagram we express it symbolically in the form of a normally closed contact(NC) as seen in ladder logic truth table shown below….

How Ladder Logic is Executed

In order to successfully read ladder logic we need a basic understanding of how a PLC works and how ladder logic is executed in a PLC. You see, the PLC follows a certain execution procedure and if not adhered to it can lead to the ladder logic being read incorrectly.

Ladder logic works in a similar way to relay logic, but without all the laborious wiring. It has supply rails, relay coils, relay contacts, counters, timers, PID loop controllers and much more. In simple terms, all the field input and output devices are wired to the PLC and the ladder logic program decides what outputs to trigger depending on the status of the input signals.

In basic terms, PLCs execute ladder logic by first reading all the input states and storing them into memory. Secondly, scanning through and evaluating each rung of ladder logic, from left to right and top to bottom. Lastly, at the end of the scan, the resultant logic is executed and the outputs are written to.

Ladder Logic Basic Functions

In a ladder diagram the normally open (NO) and normal closed (NC) contacts merely tell us what state an event is in, TRUE or FALSE. On their own they cannot decide what action to take to automate something.

We need binary’s best friend ‘logic’ to help out.

Logic is the ability to decide what action needs to be taken depending on the state of one or more events. We use the binary and logic concepts every day in our own lives. For example, if I feel cold then I put my sweater on, but if I feel hot then I take my sweater off.

Binary concept – Cold or Hot, Sweater On or Sweater Off.

Ladder Diagram Software Online

Logic concept – IF, THEN logic functions.

Binary Logic in action!

The binary and logic concepts are what makes ladder logic work. The hidden key to unlock your understanding of how ladder logic works is: The logic functions in ladder logic are are automatically built into the structure of the ladder diagram.

Let me show you……

Ladder Logic IF, THEN Functions

Let’s take a real world event, allocate it to a normally open contact (NO) and call it ‘A’. In ladder logic the real world events are defined as PLC inputs.

Now, let’s call the result of the logic function ‘Y’. In ladder logic the result of a rung logic function is defined as a PLC output.

When we take these two fundamental elements and insert them into a rung in a ladder diagram we get your first line of code!

It’s equivalent to “Hello World” in other programming languages….

Now, let’s expose the hidden inbuilt functions by highlighting them in blue in order to illustrate the relationship between the ladder diagram rung structure and its inbuilt IF, THEN functions….

We can write out the logic expression in the above as rung as IF A THEN Y.

Because PLC input A follows the binary concept it has two possible states, TRUE or FALSE. Therefore it results in two possible logic iterations:

IF A = FALSE THEN Y = FALSE

IF A = TRUE THEN Y = TRUE

We also can express this in a truth table….

If we translate this into a ladder logic diagram we express it symbolically in the form of a normally open contact (NO) for the input and a relay coil for the output. Remember the logic flow is from left to right and follows the same concept of current flow in an electric circuit.

The ladder logic truth table is shown below….

Ladder Logic AND Function

The AND function examines multiple PLC inputs and has one resulting output. If we translate an AND function into a ladder diagram we can express it symbolically in the form of two PLC inputs A and B using normally open (NO) contacts and a PLC output Y using a relay coil.

They are all connected in line, just like a series connection in an electric circuit. This time we have also highlighted the hidden AND function to illustrate the relationship between the ladder logic functions and the ladder diagram rung structure….

We can write out the logic expression above as IF A AND B THEN Y.

The AND function examines if all the PLC inputs are TRUE, then the corresponding result is also TRUE. However if any one of the PLC inputs is FALSE then the corresponding result is also FALSE.

Because PLC input A and B follows the binary concept and are part of the AND function there are four possible logic iterations. Check out the truth table below….

The number of logic iterations increases with the number of PLC inputs (2PLC Inputs). But that doesn’t matter too much with the AND function because the result can only be TRUE if all the PLC inputs are TRUE.

If we translate an AND function into a ladder logic truth table we get the table below….

Ladder Logic OR Function

The OR function examines multiple PLC inputs and has one resulting output. If we translate an OR function into a ladder diagram we can express it symbolically in the form of two PLC inputs A and B using normally open contacts (NO) and a PLC output Y using relay coil.

The inputs are placed in the rung in what is known as a branch. This is the equivalent of a parallel connection in an electric circuit. The output is then connected in line with the rung. This time we have also highlighted the hidden OR function when we create a branch (parallel connection) with PLC input B across PLC input A….

We can write out the logic expression above as IF A OR B THEN Y.

Best Ladder Diagram Software

The OR function examines if any of the PLC inputs are TRUE, then the corresponding result is also TRUE. However, all the PLC inputs must be FALSE in order for the corresponding result is also be FALSE.

Because PLC input A and B follows the binary concept and are part of the OR function there are four possible logic iterations. Check out the truth table below….

Remember, the number of logic iterations increases with the number of PLC inputs (2PLC_inputs). But that doesn’t matter too much with the OR function because the result can be TRUE if any of the PLC inputs are TRUE.

If we translate an OR function into a ladder logic truth table we get the table below….

Wow, you’ve flown through the binary and logic functions. Remember…

For basic ladder logic programming we express binary events using normally open contacts (NC) and normally closed contacts (NC).

See Full List On Plcacademy.com

The fivebasic, yet essential, logic functions in ladder logic are:

- NOT

- IF

- THEN

- AND

- OR

Naruto shippuden sound effects. You may be surprised, but when we utilize all these functions in our ladder logic programming we will be able to program the majority of automation control requirements.

Well done! You now have a handle on the basics of ladder logic.

In the next section we will jump straight into the most common symbols that you can’t do without when ladder logic programming. We’ll also examine their operation and outline some of their most popular uses. To go to the next section click here.

Ladder Logic - Wikipedia

If you’d like to learn the basics of a PLC (Programmable Logic Controller) then click here.